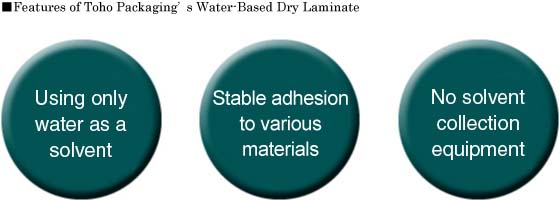

Dry laminate using water as a solvent is called water-based dry laminate. Generally, to distribute adhesive in water, the adhesive is used after being emulsified (emulsion). This is an environmentally conscious, safety laminate method that doesn’t use any organic solvent.

If the organic solvent is not fully dried in oil dry laminate printing, there is a risk of the organic solvent odder causing damage. However, the adhesives of water-based dry laminates exclude organic solvent, hence eliminating such risk. In addition, the method uses a safe water adhesive approved by the FDA.

If the organic solvent is not fully dried in oil dry laminate printing, there is a risk of the organic solvent odder causing damage. However, the adhesives of water-based dry laminates exclude organic solvent, hence eliminating such risk. In addition, the method uses a safe water adhesive approved by the FDA.

Dry lamination is a method used to coat the rear of printed films with ether or ester adhesive dissolved in a solvent via evaporation, whereby the solvent is removed during the drying process, and the film is bonded to the other rear side. This method allows wide-ranging film combinations, and is also viable for retort production depending on the selection of adhesive, as well as for recent small lot and quick deliveries.

Extrusion lamination includes a method to elution-bond polyethylene or polypropylene to the rear side of printed films to add heat-sealing characteristics, and one to extrude polyethylene between two films, just like sand-lamination, to make three-layer films at a time. In addition, a method to coextrude two or three types of resins on the surface of films has been recently put to practical use.

All these methods use polyethylenimine or an isocyanate anchor coat as usage requires, ensuring adhesion between films and extrusion resins, and are appropriate for large lot deliveries.

All these methods use polyethylenimine or an isocyanate anchor coat as usage requires, ensuring adhesion between films and extrusion resins, and are appropriate for large lot deliveries.